4-Sided Steel Box Production

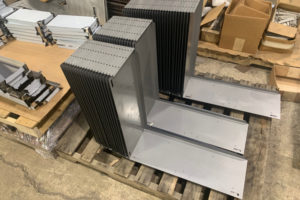

Our customer only had a sample for a project they needed fabricated. The task- reverse engineer, fabricate and zinc plate (not shown) (750) 4-sided boxes in 4 weeks during the holiday season.

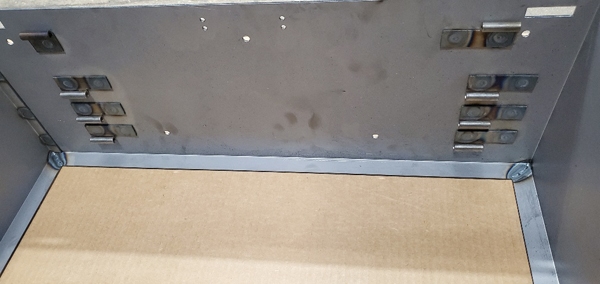

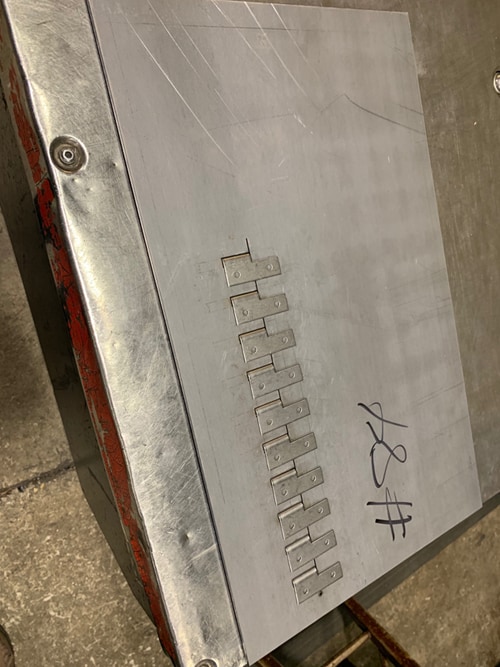

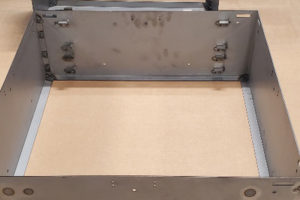

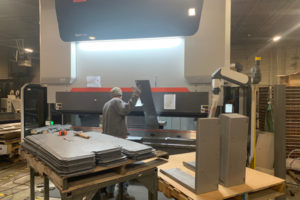

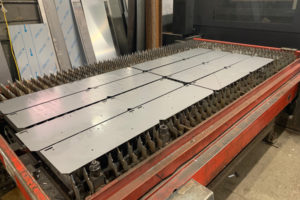

14 GA steel lasered, formed, then welded. Custom J-Hooks and custom hinges included.

A quantity of 2 boxes were made before production for customer approval.

We also included custom fixturing to hold tight tolerances needed during the welding process. All forming programs were created offline.

HIGHLIGHTS OF THIS MILD STEEL BOX PORTFOLIO PROJECT

- Product Description

14 GA CRS, 4-sided box

- Capabilities Applied

- Reversed Engineering

- Fixturing

- Laser

- Form

- Weld, Spot Weld, Plug Weld

- Machining

- Grinding

- Production

- Shore Turnaround

- Zinc Plating

- Overall Part Dimensions

Material Thickness- 14 GA Steel

Length: 36″

Width: 36″

Height: 12″

- Surface Finish

Zinc Plated

- In Process Testing/Inspection

- Dimension inspected

- Product tested and approved by customer before production released

- Estimated Part Weight

15 pounds

- Industry

Processing

- Quantity

750 units

- Turnaround Time

4 weeks

- Location

Chicago Area

- Standards Met

- Customer provided product sample

- Multimetal reverse engineered, etc.

- Product Name

4-sided Box

14 GA CRS

Back to Top!